Technical Advice

Floor Gully Trap Installation Manual

Floor Gully Trap Installation Manual

Step 1

Step 2

Step 3

Step 4

Step 5

Be sure to use good quality PVC solvent cement (PVC glue) to join bottom outlet to the base of the body.

Step 6

Make sure to fully push the bottom outlet into the body under concrete soffit before joining the fitting by others to start piping work.

Step 7

After completed install bottom outlet, joining the fitting by other to start piping works.

Step 8

After water proofing or ponding test, remove black cap and place collar into position. Ensure it sits perfectly in body trap and during cement screeting to suit collar and tile laying level.

Step 9

Make sure collar is flush with tiling work to ensure smooth flow of water in future.

Step 10

Drop in bowl/container into body for water seal and future ease of maintenance.

Step 11

Also drop the bell cap into container for completed water seal.

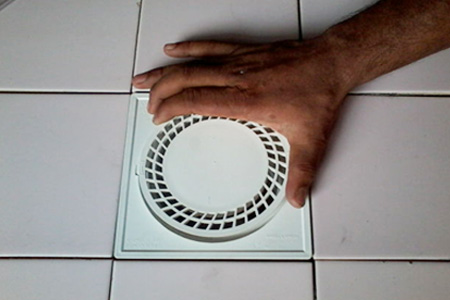

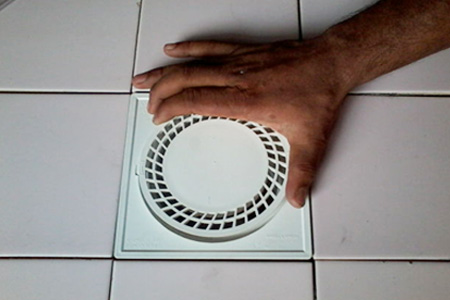

Step 12

Lastly, drop in grating to complete installation of floor trap.

Floor Gully Trap Installation Manual

Floor Gully Trap Installation Manual

Step 1

Step 2

Step 3

Step 4

Step 5

Be sure to use good quality PVC solvent cement (PVC glue) to join bottom outlet to the base of the body.

Step 6

Make sure to fully push the bottom outlet into the body under concrete soffit before joining the fitting by others to start piping work.

Step 7

After completed install bottom outlet, joining the fitting by other to start piping works.

Step 8

After water proofing or ponding test, remove black cap and place collar into position. Ensure it sits perfectly in body trap and during cement screeting to suit collar and tile laying level.

Step 9

Make sure collar is flush with tiling work to ensure smooth flow of water in future.

Step 10

Drop in bowl/container into body for water seal and future ease of maintenance.

Step 11

Also drop the bell cap into container for completed water seal.

Step 12

Lastly, drop in grating to complete installation of floor trap.

INFO

SPIND MALAYSIA SDN BHD

38, Jalan Utama 1/2,

Taman Perindustrian Puchong Utama Sekysen 1,

47130 Puchong,

Selangor.

Tel: 603 8060 5500

Fax: 603 8060 5511

Email: info@spind.com.my

Sales Inquiry:

+6012-249 9821 (Mr. Ngai)

+6019-282 0972 (Mr. Cheong)

PRODUCTS & SERVICES

CONTACT US

PRODUCTS & SERVICES

CONTACT US